Typically, moulding plywood requires a former for each type of profile that is created. This normally requires a extensive range of tools, skill sets and resources.

While they can be reused to produce duplicate moulds, it is the biggest roadblock to projects with low volume runs, a high number of unique profiles, or limited access to tools.

These formers are often large in size, making them difficult to store and often forcing manufacturers to either commit valuable space for keeping them or immediately dispose of them to remake when they are required.

Whereas traditional methods of moulding plywood are almost exclusively dependent on the use of a former, the motivation behind DMP was to create a system of moulding plywood that doesn't use any kind of former to shape the plywood.

Instead, DMP utilises Digitally Aided Manufacturing techniques to directly machine the plies so that when placed in a vacuum bag with a universal aligning piece, they automatically adopt the intended form.

The principle behind DMP is based on the knowledge that if two plies of different lengths are aligned at their starts and ends, there will have to be a relative angle change throughout the system to accommodate full contact between the layers. If the difference in lengths is larger, so is the relative angle change.

While differences in length create an angle change, it is impossible to predict this angle change without also knowing the thickness of the pieces (or more accurately, the offset between the separate bending axes), as this greatly affects the resultant angle change even in pieces with the same lengths.

Therefore, if the thicknesses of the plies is known, and alignment at the start and ends is ensured, full contact between two surfaces will result in a predictable angle change in the system. However, to ensure accurate forming of a desired profile, a predictable angle change is insufficient.

In order to have complete control over the profile parameters, the relative position of contact between the plies needs to be guaranteed throughout the entire length. After extensive prototyping, a universal spine was designed to provide this alignment throughout the piece, which - when combined with appropriately machined plies - would give the ability to create an infinite range of

With this ability to forgo the creation of a former, creating complex pieces comprising of multiple moulded profiles becomes drastically cheaper and more achievable, assuming you have access to a 3-axis CNC and the ability to generate the desired toolpaths. The creation of these toolpaths, something that requires extensive calculations for every new profile to be formed, is easily managed by the use of generative design software, such as grasshopper.

An internal view showing the position of the guiding spines within the plywood

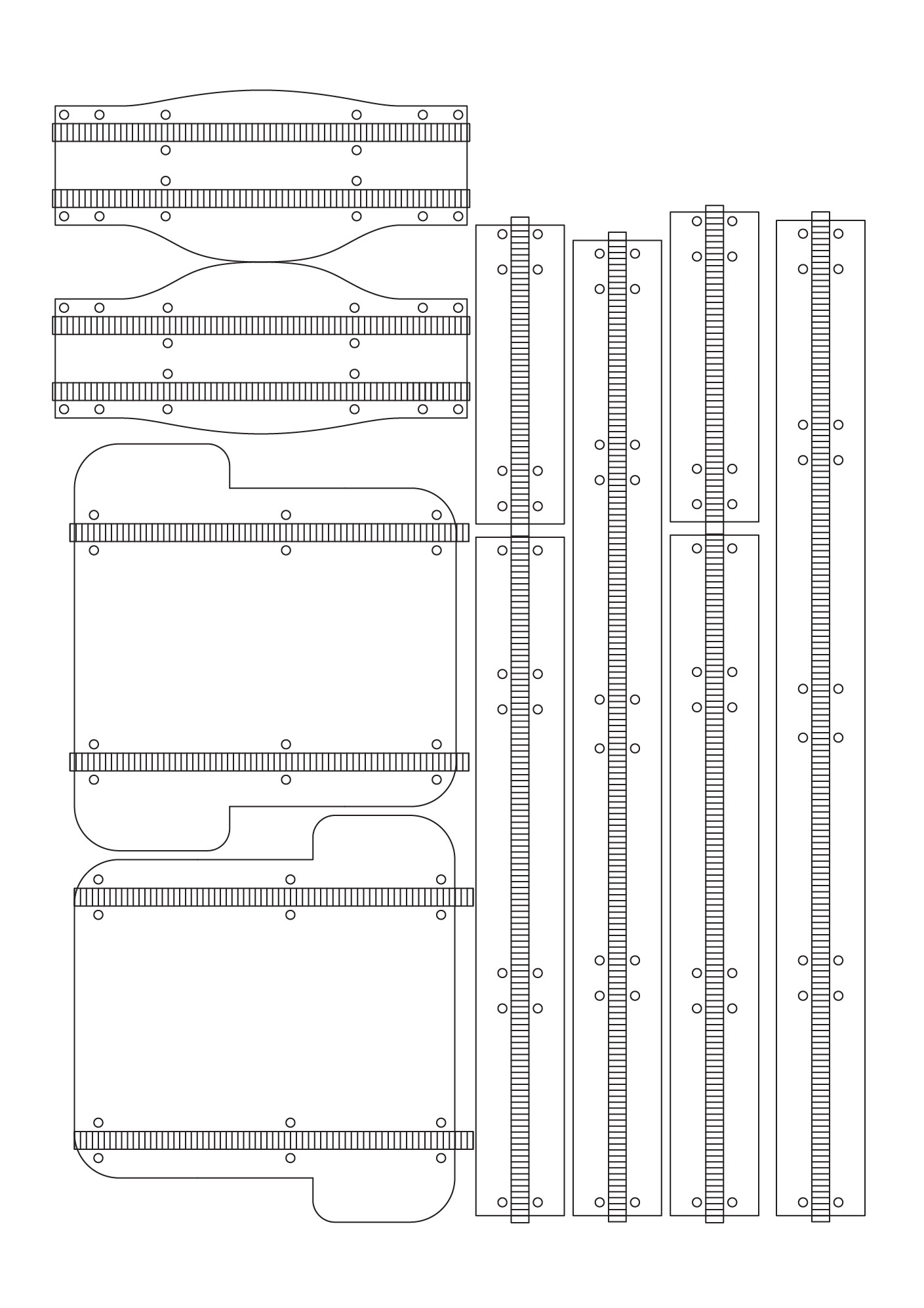

The design 'unfolded' through the grasshopper algorithm into tool paths ready for the CNC

This chair was made using only a basic 3-axis CNC router and a vacuum bag.

The project in exhibition at the 2019 RCA Degree show, where it won the Ki Award